Workflow

How efficient is myQA SRS in terms of workflow?

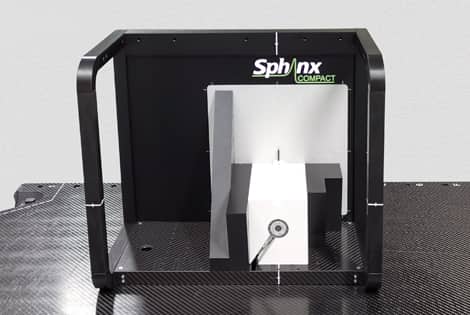

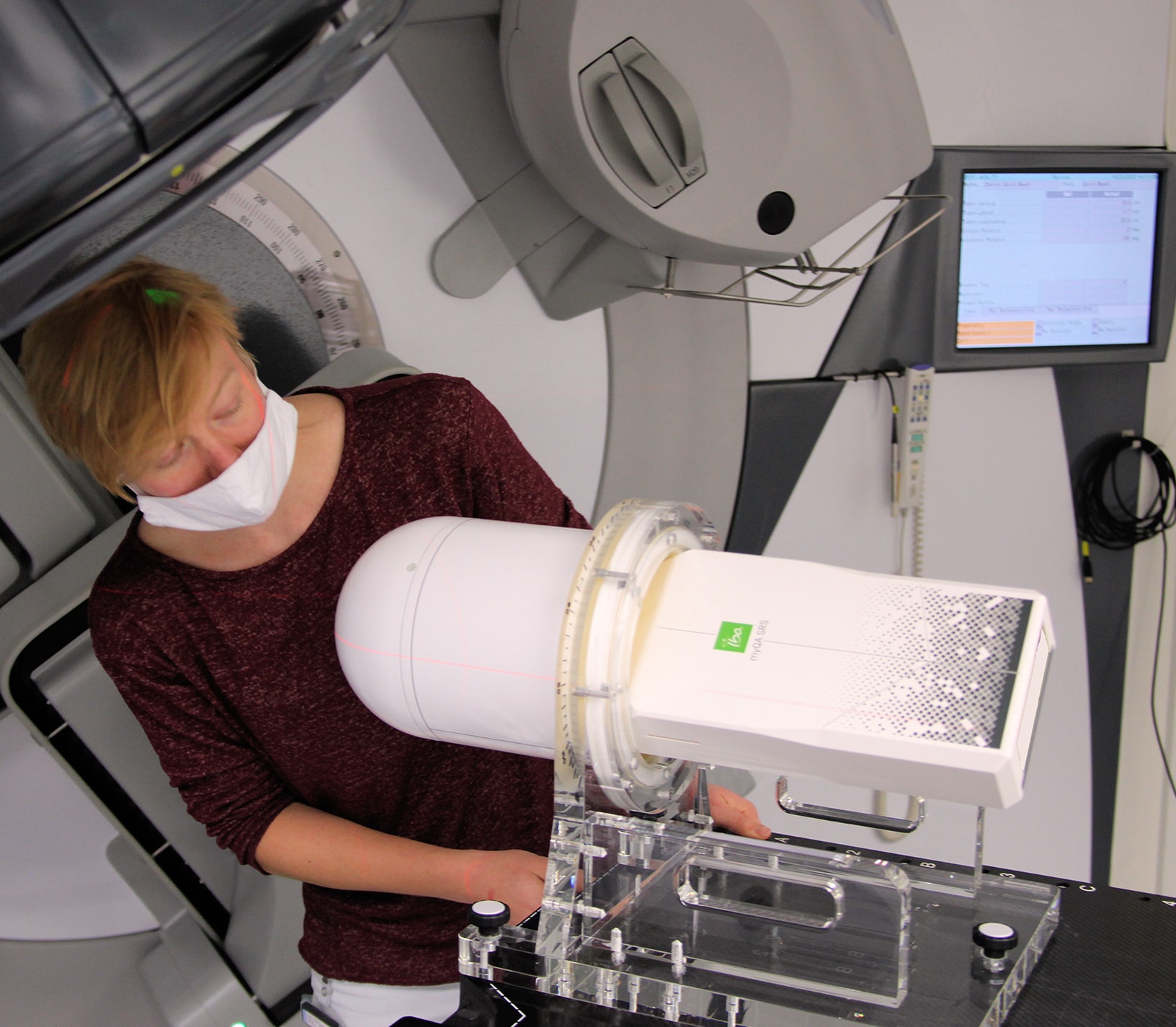

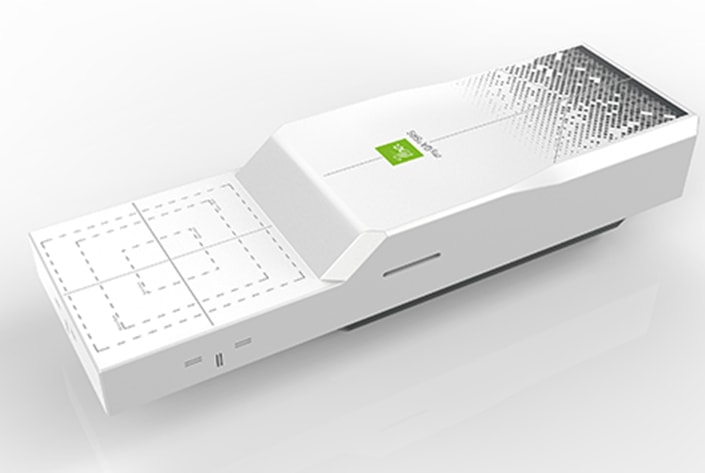

- Efficiency compared to Film QA: myQA SRS offers the workflow efficiency of digital detector array solutions. Simply position myQA SRS and the SRS Phantom on the Linac couch, irradiate the plan and validate the measurements in the myQA software. The whole myQA SRS process takes less than 10 minutes.

- Efficiency compared to conventional detector arrays: The overall workflow is substantially equivalent. However, the film-class resolution of myQA SRS prevents false positive QA results, and therefore overcomes time-consuming searches for the source of the errors or re-planning or re-measuring.

Overall, myQA SRS enables the fastest workflow of any alternative solution.

How is the setup on the couch / is there an indexing bar?

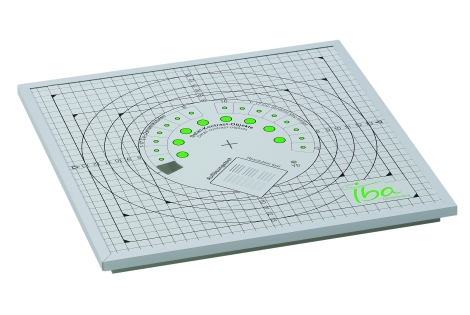

The myQA SRS Phantom has dedicated indexing bars to ensure a fast, reproducible, and stable setup and positioning on standard Elekta® and Varian®1) tables.

Clinical Application

Which types of SRS and SBRT QA plans are supported?

myQA SRS detector supports static beams, arcs (static & dynamic) for SRS cones and MLC, IMRT and VMAT deliveries.

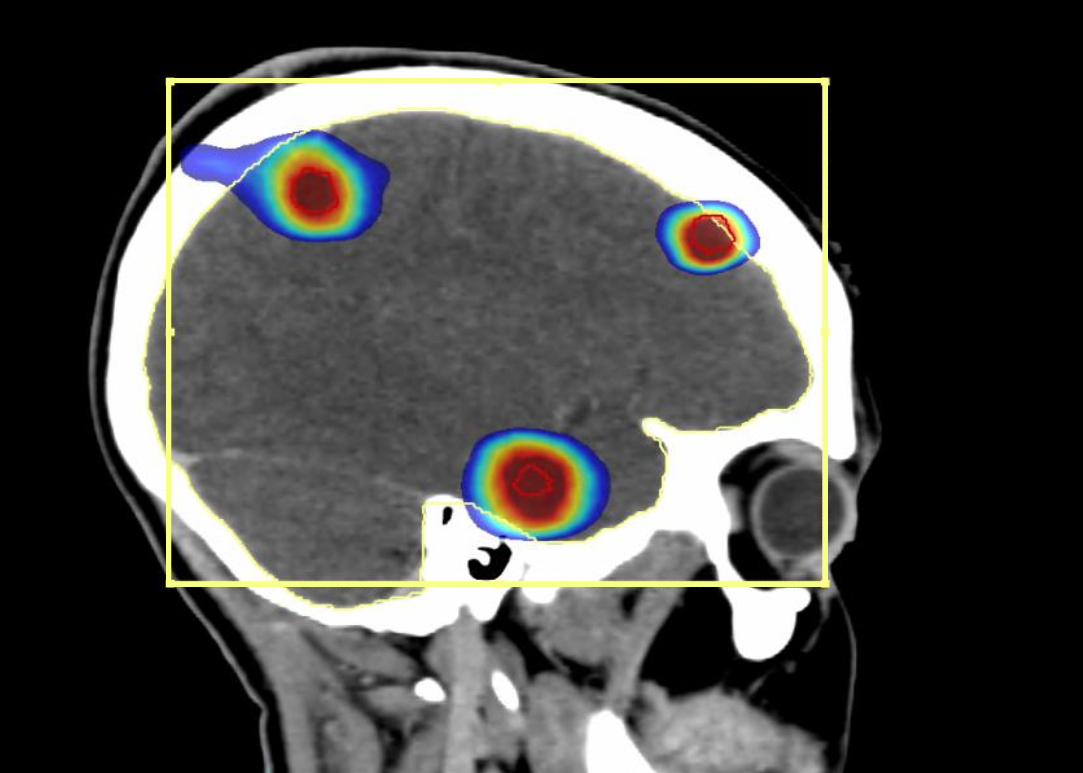

Why does detector resolution matter for QA of stereotactic cases?

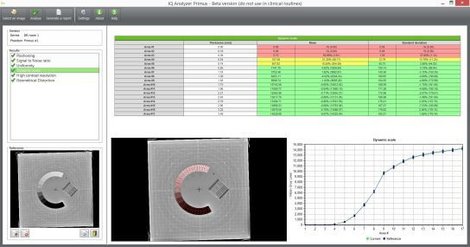

Multiple studies have been conducted with the goal to evaluate the clinical significance of QA results provided by conventional detector array solutions. These studies conclude that the detector resolution is the main factor that determines the quality of the outcome. High detector resolution helps to avoid false QA results, and therefore increases the quality and workflow efficiency. The publication from the University College London concludes: “detector resolution is of main importance to avoid getting false positive [QA results]” (A. Bruschi, University of Florence, Italy). Detector resolution affects the clinical significance of SBRT QA. Find link to Publication here.

How can I perform my stereotactic patient plan QA with myQA SRS?

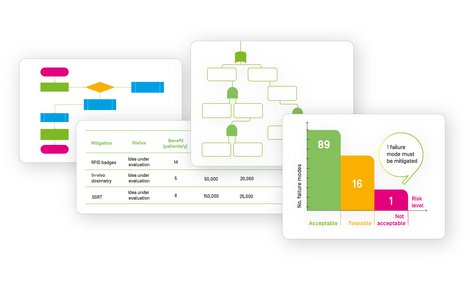

All plan verification methods described in the AAPM TG-218 report are possible with myQA SRS. The following plan QA options are supported:

- Delivery with all couch and gantry angles set to zero degree (total composite delivery).

- Delivery with several fixed gantry angles with the myQA SRS detector rotated with the phantom (perpendicular field-by-field delivery).

- Delivery with native gantry and couch angles as applied in your real patient treatments. For rotational cases the Gantry Angle Sensor+ is recommended.

Are rotational treatments and non-coplanar fields supported by myQA SRS?

The compact design of the myQA SRS detector and SRS Phantom with its cylindrical shape and rounded cap provide the needed clearance for QA measurements of all typical SRS beams and arcs, including non-coplanar beams.

The system is designed to support* in-line and perpendicular setup in the Varian® Ethos™ and Halcyon™.

The Gantry Sensor+ provides accurate measurements of your Linac rotation angles corresponding to your detector measurement.

*Validation is ongoing

Can the myQA SRS be rotated?

Yes. The myQA SRS detector can be rotated seamlessly in 360 degrees within the phantom. Find more at the following FAQ: “How can I perform my stereotactic patient plan QA with myQA SRS?”

Does myQA SRS support multiple target QA?

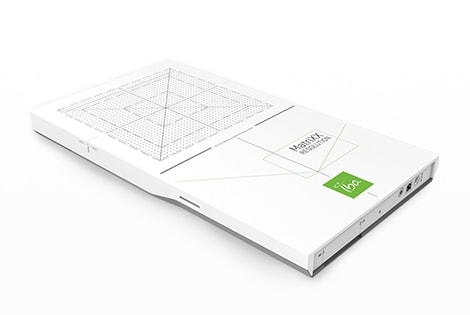

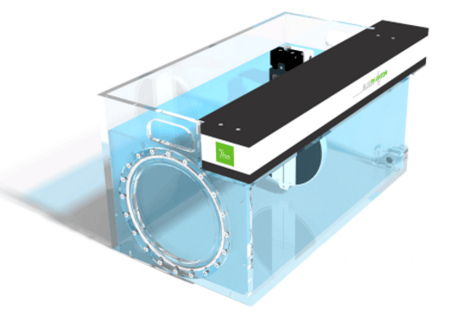

Yes, myQA SRS provides the largest active detector field with full SRS resolution of any existing dedicated stereotactic detector array. The large 120x140 mm² active array enables multiple targets to be measured in a single setup. The myQA Patients software allows you to validate all targets simultaneously.

What SRS / SBRT delivery systems are supported by myQA SRS?

myQA SRS supports all SRS and SBRT systems. 1)

- All standard and stereotactic C-arm Linacs

- MLC and cone-based SRS systems

- Varian® Ethos™ / Halcyon ™

- CyberKnife® MLC, Iris or Cones *

- TomoTherapy® / Radixact® *

- BrainLAB Novalis®

* Validation testing is a work in progress. myQA SRS might not be available for sale for certain systems.

1) All product and company names are trademarks or registered trademarks of their respective holders. Use of them does not imply any relationship,

Is myQA SRS TG 218 compatible?

Yes, myQA SRS is fully compatible with TG 218.

- myQA SRS measurements are to be performed in True composite (TC) delivery method.

- Measurements can also be performed in the Perpendicular field-by-field (PFF) delivery method for TC verification error analysis.

- Angular dependence is accurately accounted for.

- Measurement analysis is performed in absolute mode.

- Global and/or local or reference dose normalization can be used.

- QA plans can be delivered in the native geometry, including couch kicks.

Detector

What are the advantages of the solid-state detector technology used in myQA SRS?

myQA SRS uses a unique sensor technology based on CMOS technology (complementary metal-oxide-semiconductor) which allows a compact design, fast read out and high pixel density on both dimensions. This technology has been validated and published: As described in Jimenez-Spang. F et al “Photon small-field measurements with a CMOS active pixel sensor” (Physics in Medicine and Biology, May 2015), each pixel is a light radiation sensitive element with a photodiode, a capacitor and three transistors. After ionizing radiation interact in the pixel sensitive volume, the generated electrons are collected by the diodes implanted into the pixel volume and the collected charge is integrated by the action of a capacitor in each pixel. Find link to Publication here.

Most traditional patient QA devices are ion-chamber-based. Is this new solid state technology capable of matching the performance of ion chambers in terms of output measurements?

Only myQA SRS offers Film-Class resolution in a digital detector solution. All other detector arrays rely on either diodes or ionization chambers. Whilst especially ionization chambers have a proven and reliable track record for conventional Radiation Therapy QA like IMRT and VMAT, they don’t allow for sufficient measurement resolution needed for the extreme dose gradients seen in SRS cases. Standard and even “pseudo SRS” detectors face technical limitations in terms of possible resolution and have a significant percentage of the detector area between the actual pixels where no data can be measured. To compensate for this lack of measured data, dose interpolation is typically applied to “fill the data gaps.” Although this is acceptable for conventional treatments, the resulting low measurement resolution and need for interpolations are main factors for getting false positive QA results.

What are the differences between myQA SRS and EPID detector technologies for Patient QA measurements?

There are several important differences between myQA SRS and EPID detectors for use in Patient QA:

- myQA SRS uses a different sensor technology compared to EPIDs. The myQA SRS detector is built of CMOS Si-photodiodes, without the typical scintillator layer used in EPIDs. With a frame rate of 70 frames/second, myQA SRS processes a larger amount of information than a typical EPID.

- myQA SRS is designed and optimal for dosimetric measurements needed for a comprehensive patient plan QA, and its detector provides a direct signal to dose. In contrast, the EPID was originally designed as an imaging device and provides pixels of different intensities which are then converted to dose.

- Pre-treatment plan verifications with myQA SRS follow international protocols (e.g., TG-218), allowing users to perform verification at isocenter and with precise angular corrections, measurements with couch rotations, etc. In contrast, EPID measurements are always done perpendicular to the beam, a method known as error masking. Non-coplanar measurements are limited with EPIDs.

- EPID is known for issues such as ghosting, overresponse to low energy photons, backscatter from arm, gravity, and angle uncertainty that all negatively impact the quality of the QA result. None of these EPID limitations are present with the myQA SRS detector.

Solid state detectors can have an angular-dependent response. How has myQA SRS mitigated this effect?

For VMAT or IMRT deliveries with native gantry angles, the wireless Gantry Angle Sensor+ is used to record the actual positions of the gantry and transmit them aligned with the measured dose date. The detector response is corrected for the angular dependency by software using angle-specific correction factors derived from Monte Carlo simulations and beam quality information.

Alternatively, the SRS Phantom including the inserted myQA SRS detector can be rotated flexibly to enable perpendicular beam measurements of multiple SRS beam configurations.

Is there an initial calibration performed?

myQA SRS is delivered with factory calibration. User uniformity correction might be advised after 1 year in case of detected deviations.

Can I perform absolute dose measurements with the myQA SRS detector?

Yes, measurements in both relative and absolute modes are supported. Precise absolute dose calibration for Patient QA measurements can be done based on the TPS preference, measurements with Farmer-type chamber, or film with help of the dedicated film and chamber inserts in myQA SRS Phantom.

To the myQA SRS product page

We hope that your initial questions about the myQA SRS have been answered. For more information, please visit the product page or use our contact form for further questions.